Solution to transform

Traditional Factories Into SMART In 15 Minutes

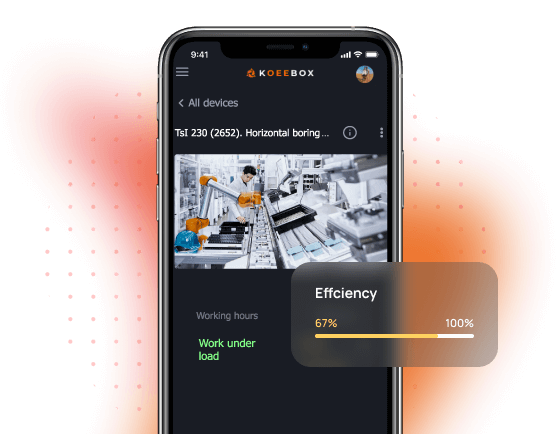

Control the operation of your equipment remotely and in real-time, find weaknesses, and improve all processes in your production.

Try it free

01

Availability02

Performance03

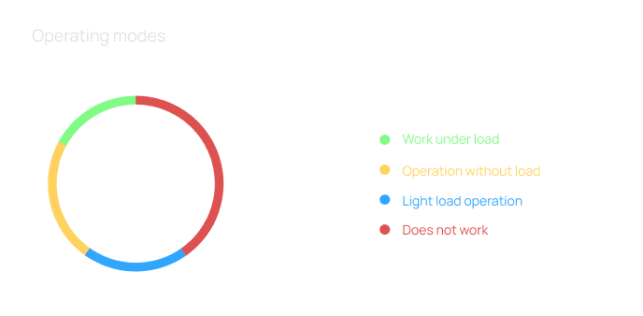

QualityWhat is measured by K OEEBOX ?

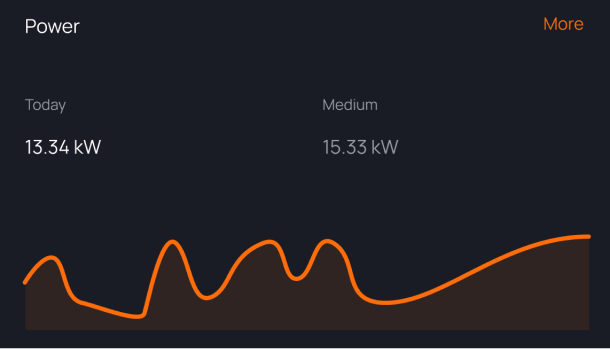

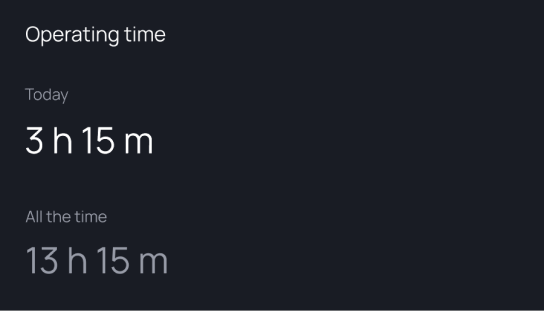

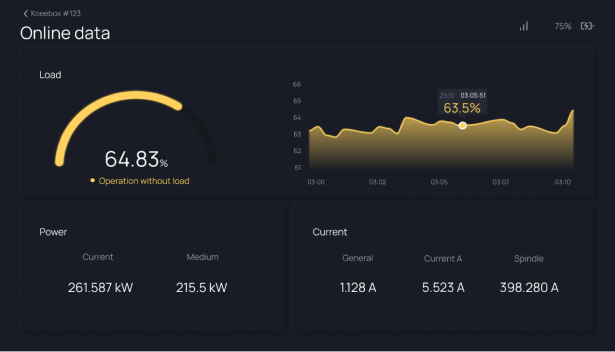

KOEEBOX is a hardware solution installed on the power cable to ensure power measurement. Overall Equipment Effectiveness is a gold standard for measuring production efficiency.

High OEE is a sign of high efficiency. Low OEE means that there is a 'hidden factory' eating into your resources and profits.

What Problems Are Solved By K OEEBOX ?

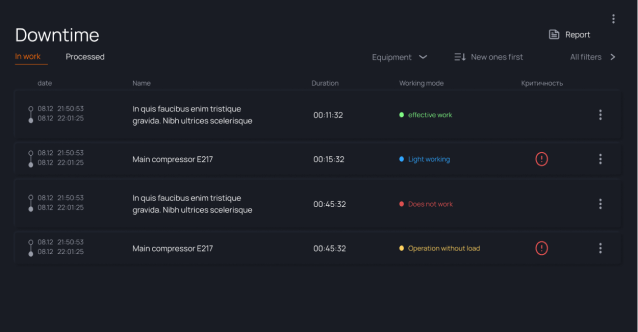

Weak points in production

Get the data to analyze and improve your production performance.

No time for things that really matter

Understand the duration and causes of downtime. Prioritize job orders for the production crew.

Paperwork

Get rid of redundant paperwork with automated data collection.

Human factor

Benefit from error-free data with our solution.

Time To Go SMART

01

Get a KOEEBOX.

02

Choose any electric-powered equipment.

03

Install the sensor right on the power cable.

04

Run your KOEEBOX and get instant results!

Why KOEEBOX?

Universal

Runs on any equipment

Quick to install

Install in 15 min - no expert team required

Easy to use

Comfortable work. Handy, intuitive interface

Infrastructure

No infrastructure or administration needed

Mobile

Mobile connection and smartphone support

Free month

All the benefits of SMART production within 1 month

What Does KOEEBOX Look Like?

KOEEBOX Capabilities

Get started free with K OEEBOX

Get a one month of complete control over the equipment and processes in your production and modernize your factory in accordance with Industry 4.0 technologies.

)

)