How Does Vibration Analysis with KOEEBOX Help to Prevent Equipment from Stopping?

In modern factories, it is no longer enough to maintain and repair in a timely manner – it is now possible to identify and repair damage even before the production system fails. One of the most common ways to fix such damage is to analyze the vibration of the equipment.

What Information Does the Vibration Level Provide?

Every time the life of the components of the rotary equipment comes to an end and wear out, the intensity and nature of the vibration change. Therefore, it is based on these indicators that it is possible to classify equipment failures and develop an effective downtime prevention plan.

A skilled person or artificial intelligence, based on the results of vibration analysis, can predict many causes of failures, for example:

- misalignment of components;

- bearing supported wear;

- shaft deformation;

- loosening of bolts;

- mechanical defects of gears;

- short circuit in the starter winding;

- power supply problems.

Having discovered these or other failure factors, the specialists of the enterprise can repair or replace equipment components in advance, preventing a complete stop of damage to products or injury to workers.

How Is Vibration in an Enterprise Measured?

To accurately measure and quickly analyze vibration on pieces of equipment, KOEEBOX sensors can be used. Having a connection to the mobile Internet, they continuously transmit data to the cloud, and you can view the information in a special web application. When potential deficiencies or shutdowns in the operation of key nodes are detected, the devices send notifications to employees of the enterprise so that they can eliminate errors as soon as possible.

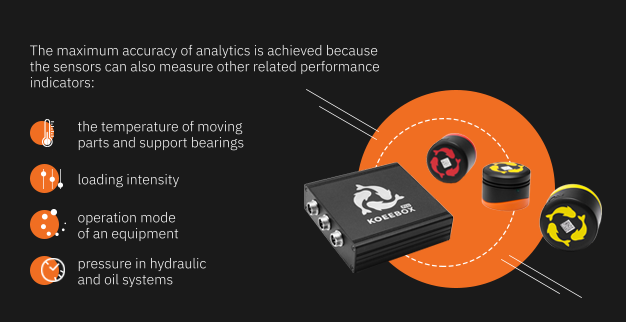

The maximum accuracy of analytics is achieved because the sensors can also measure other related performance indicators:

- the temperature of moving parts and support bearings;

- loading intensity;

- operation mode of an equipment;

- pressure in hydraulic and oil systems.

The most comprehensive measurement of equipment performance and their qualitative interpretation allows you to create objective forecasts of the technical condition of production assets.

By combining KOEEBOX sensors with Industry 4.0 software solutions for factory automation such as SmartEAM, you can build production processes with maximum efficiency and minimize the consumption of raw materials, energy, and human resources.

Find out how KOEEBOX can improve your production efficiency. Leave a request at the link https://koeebox.com and get a month of free testing of the equipment control system.